A custom-built chassis capable of handling modern power.

VIGILANTE

A best-in-class chassis.

JeepHeritage has been restoring classic Jeeps for over 20 years focusing on Wagoneers, Grand Wagoneers, Cherokees, and J-trucks.

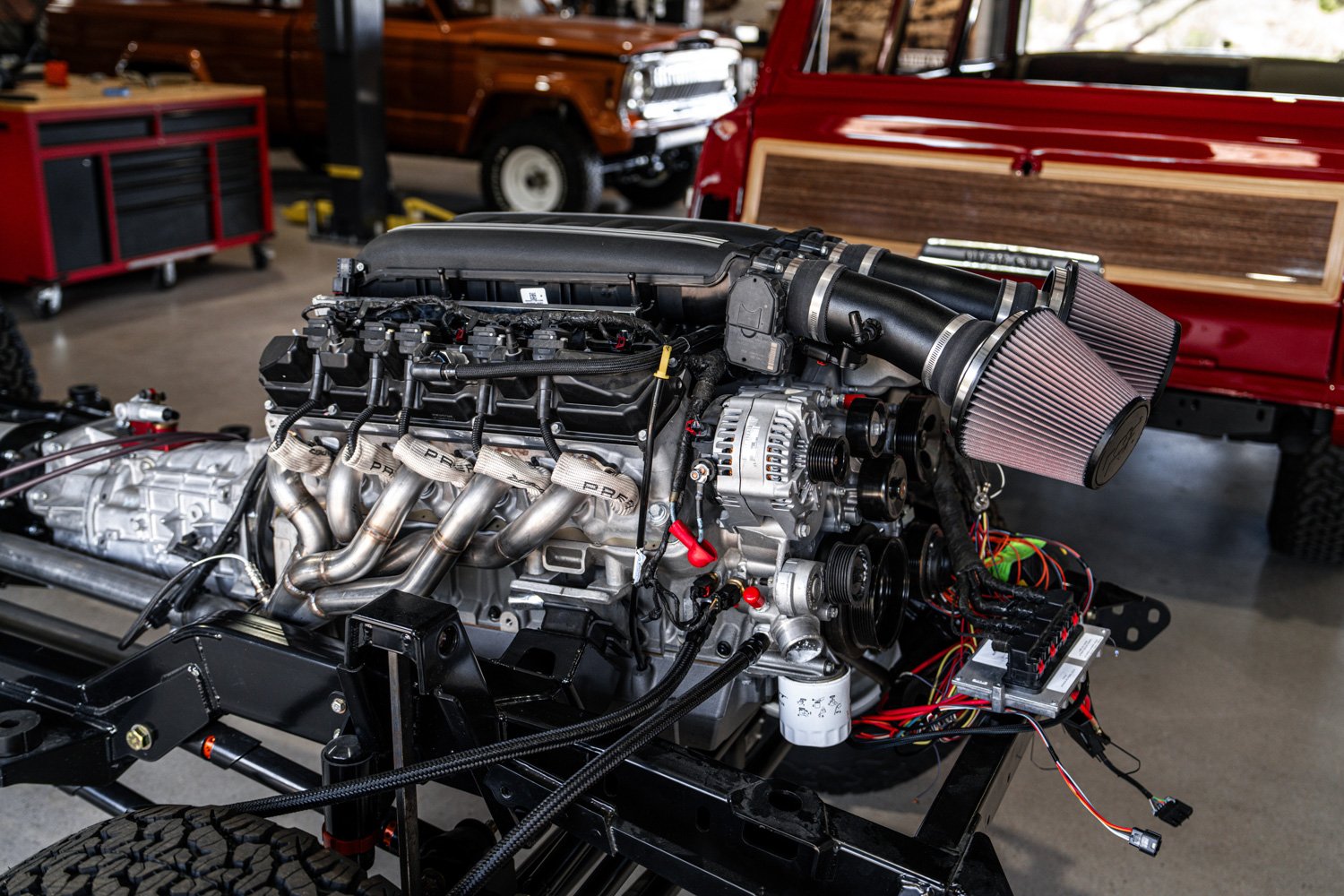

VIGILANTE is the perfect mix of quality restoration expertise, fully updated and properly re-engineered platforms, and modern drivetrains. The chassis is custom-built to the highest standards and allows us to integrate the power of high-performance HEMI engines responsibly.

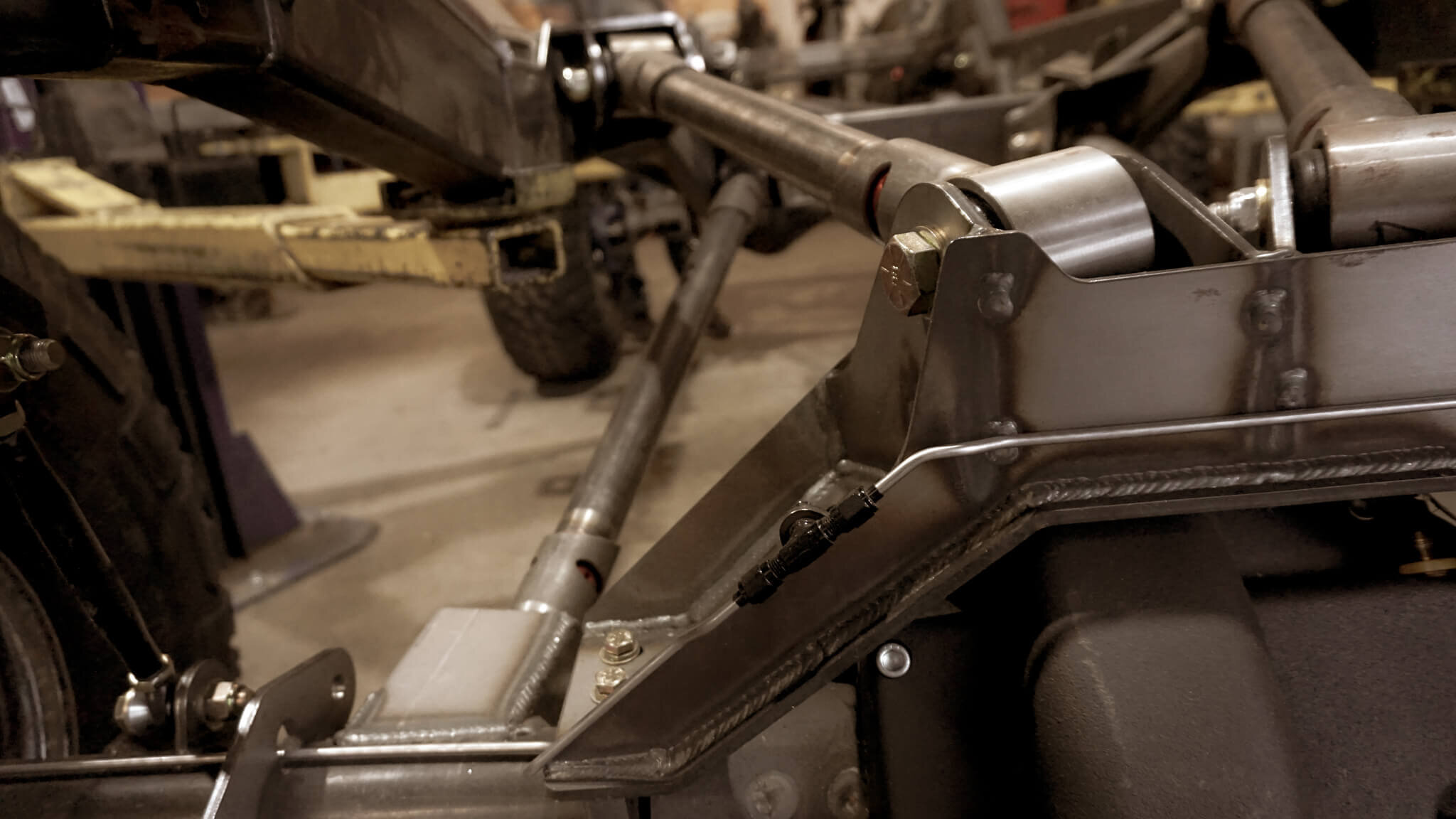

We have surrounded ourselves with the best people in the industry for the design of a custom-made platform that provides improved handling, accommodates powerful acceleration, and holds brakes that are equivalent to those found modern high-end SUVs.

Find out more with Rachel.

In this short video, Rachel van Doveren introduces the VIGILANTE chassis.

How it all happened.

Conception

The original chassis of these classic vehicles were not a viable option to handle 450 to 1000 horsepower, so we had to create a new and stronger one from scratch. A chassis that would be able to carry all the high-performance components used in VIGILANTE.

To create this new chassis, we started with complete 3D scans of the original bodies of a 1965 JEEP J2000, a 1966 JEEP WAGONEER and a 1980 JEEP CHEROKEE CHIEF. Through these scans, we were able to extract all the bodies’ original anchor points.

Then, based on these scans, we created CAD (Computer-Aided Design) documentation and started the design of the new platform.

Through this process we were able to incorporate the necessary components into the 3D model, and thus ensure the perfect fit.

Prototype

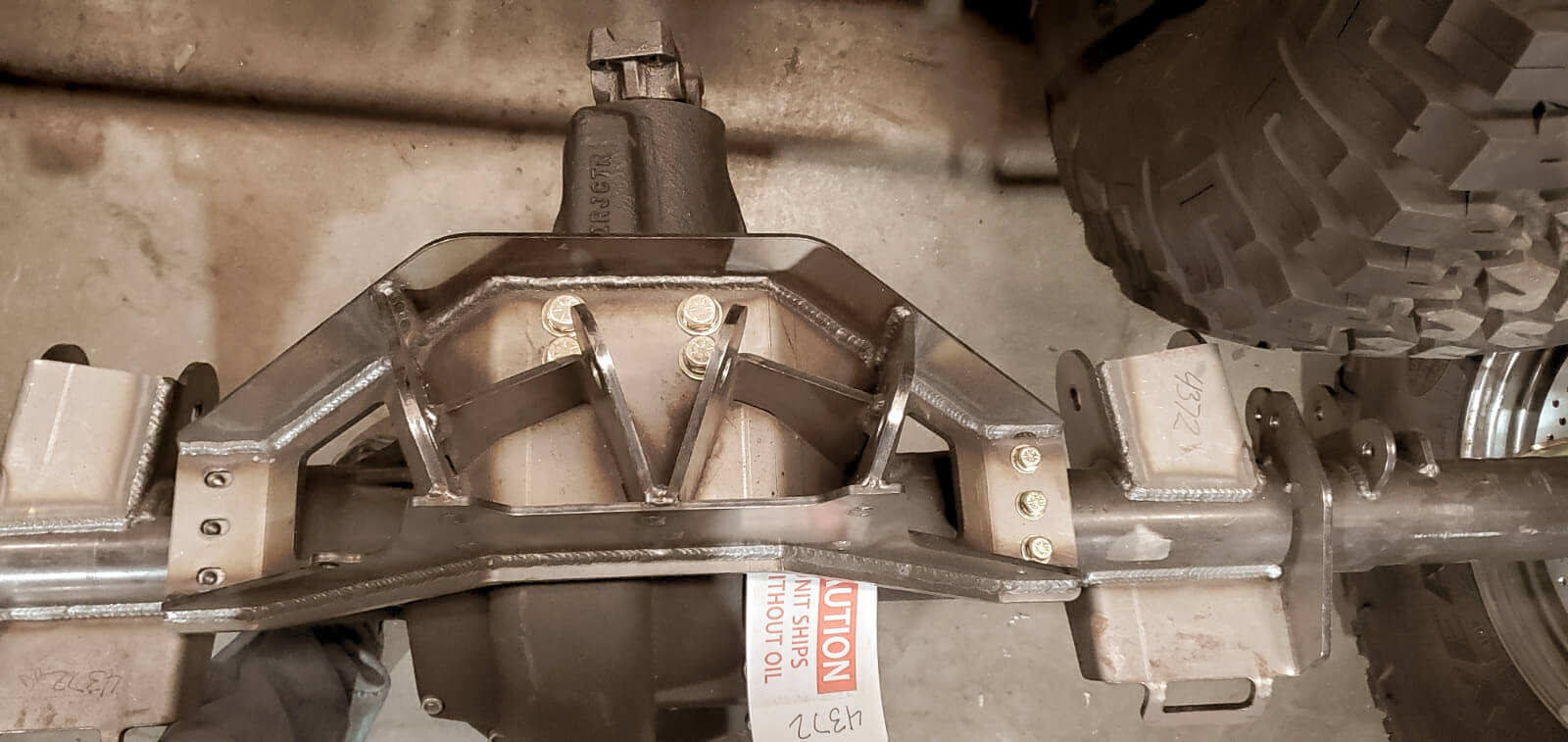

Based on this 3D model, a physical prototype was created in 5mm steel (instead of 3mm in the original chassis). The real components were then assembled onto that prototype (engine, transmission, transfer case, axles, and suspension components).

Testing

Once the physical chassis was completely assembled, we tested the assembling of the chassis and body again to make sure they fit perfectly. During testing, we testfited all Jeep Full-Size body styles (Grand Wagoneer, Wagoneer, Cherokee, and J-truck), and we merged thjem with the different HEMI engines we are offering (5.7L, 6.1L, 6,2L, 6.4L, and 7.0L).

A successful outcome.

Finishes

The chassis goes through a finishing process that ensures it will last longer than the original: sandblasting, powder coating, cavity coating all happen before final assembly.

“The creation of this platform was a real challenge. It was complex and long, but the perseverance paid off. Thousands of hours of work were necessary and have been rewarded with this exceptional result that we are proud to offer through VIGILANTE”

Daniel Van Doveren, CEO Vigilante